A Pictorial Booklet On

Early Jamestown Commodities And Industries

By J. PAUL HUDSON – Illustrated by Sidney E. King

1957

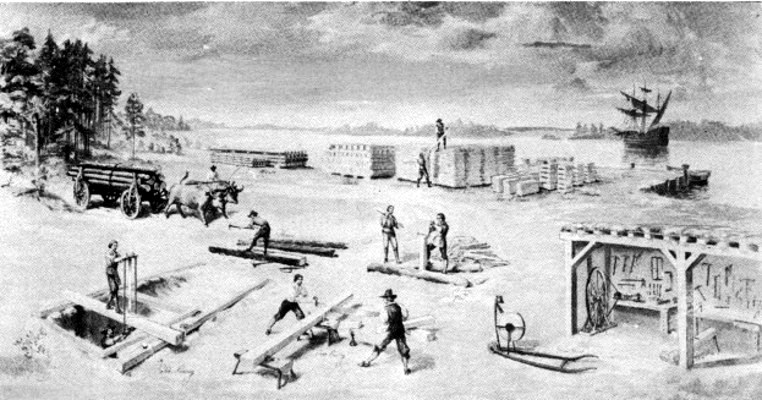

Boat Building on the Black River

BOATBUILDING

“On April 27 1607, the day after the Jamestown colonists landed at Cape Henry, some of the settlers began to build or assemble a small boat. George Percy, one of the original colonists, reported that it was completed and launched on April 28.

It appears, therefore, that 350 years ago—on the sandy b”each near Cape Henry—the Jamestown bound colonists made their first important commodity by hand in the New World.

“Contemporary records reveal that many small boats were built at Jamestown from the earliest years of the settlement. They afforded the best means of transportation through the uncharted wilderness, and were used for fishing, trade, and exploration.

Boatbuilding tools – Hand forged from iron

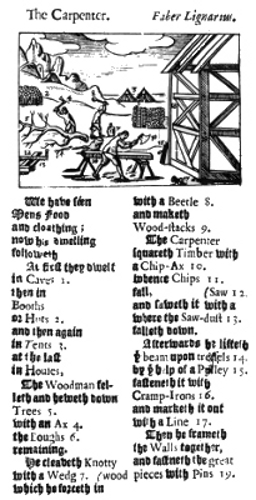

Timbering

“Timbering was one of the first activities undertaken by the Jamestown colonists and was one of the first English industries in America. The day the settlers arrived they began cutting down trees, for timber was needed to build their fort and town as well as to export to the mother country. Thomas Studley, a member of the first colony, reported that clapboards were made for loading on the ships which were to return to England:

‘Now falleth every man to worke, the Councell contrive the fort, the rest cut downe trees to make place to pitch their tents; some provide clapboard to relade the ships, some make gardens, some nets, &c.’

“Captain Newport left Jamestown in June, 1607 and aboard his two ships were clapboards and other wooden products.

“The virgin forests growing in the vicinity of Jamestown furnished planks, masts, clapboard, wainscoting, and other wooden products needed by the mother country. As England had run short of timber and was paying exorbitant prices to European countries for naval stores and timber products, the supply furnished by the Jamestown colony helped greatly to relieve the situation. The Virginians were also helped, for timber was one of the few products which brought profits to the struggling colony.

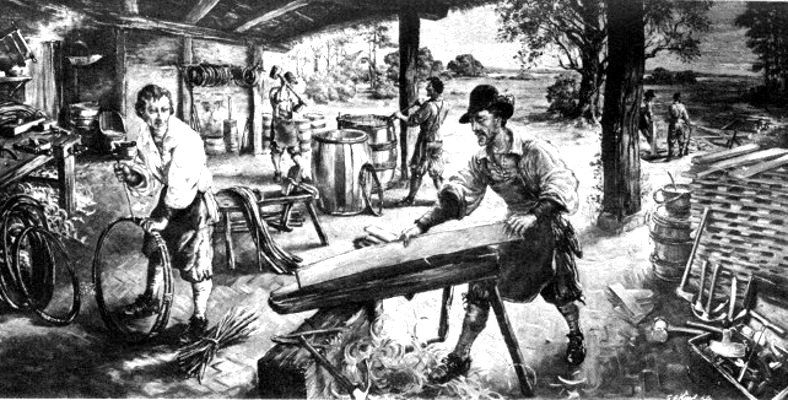

Coppers and Casks

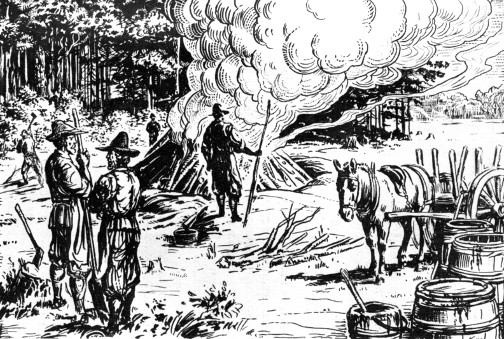

“The illustration shows a cooper and his helpers making barrels and casks at Jamestown, about the year 1625.

“As early as 1607 barrel staves were made at Jamestown for exporting to England. Later, when tobacco and other crops were grown successfully—and a few commodities were produced in Virginia for export—barrels, casks, and other wooden containers were made by the cooper in large numbers.

“John Lewes was the first cooper to reach Jamestown, arriving in January, 1608. Others followed him throughout the seventeenth century; and for almost a hundred years their craft was an important one in the ‘Capital Cittie.’

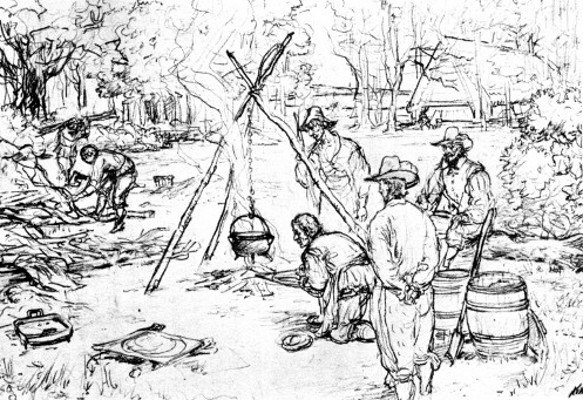

Pot-As

“Soap-ashes and potash were among the first commodities produced by the English in America. Potash was made from soap-ashes (wood ashes, especially those obtained from burning ash and elm) and was used at Jamestown for making both soap and glass. Soap-ashes were exported to England as early as 1608, and throughout the remainder of the century it appears that both potash and soap-ashes were shipped to the mother country, As early as 1621 soap-ashes were selling for six shillings to eight shillings per hundred weight, whereas potash was bringing between thirty-five shillings and forty shillings per hundred weight.

“Although few contemporary records are available which mention the profit made from the sale of soap-ashes and potash by the Virginia planters, it is known that some small returns were made from time to time throughout the seventeenth century. While tobacco was the important money-making crop, the part played in the economy of the Jamestown settlement and environs by other commodities—including soap-ashes and potash—should not be overlooked.

“In the conjectural picture Jamestown settlers are shown making potash. Five steps were necessary:

1. A pile of firewood (billet-wood) was burned until grey ashes

were formed. The best woods were oak, ash, poplar, hickory, elm,

hazel, and beech. Old hollow trees, if not dead, were especially

desirable.

2. After several pounds of ashes had accumulated, they were leached

(boiling water was percolated through the ashes), resulting in a

very strong alkali solution known as ley or lye.

3. The alkali solution (or ley) was strained through a coarse linen

cloth to keep out any coarse materials (such as small pieces of

half-burnt wood), that might happen to remain in the ashes.

4. The strained ley solution was poured in an iron pan, and

evaporated over a quick fire—almost to dryness.

5. The residue remaining in the bottom of the pan was removed and put

into an iron pot. The pot was put over a strong fire till the matter was

melted. Immediately the melted matter was poured out upon an iron plate,

where it soon cooled and appeared in the form of a solid lump of

potash.

“To a chemist the somewhat primitive methods described are very obvious ones in making an impure form of potash. The combustion of hardwoods resulted in an ash residue containing the desired potassium carbonate. Some purification was obtained by leaching the ash residue in boiling water and then filtering the “ley” through a coarse linen cloth. The filtered “ley” was evaporated in an iron pot to dryness. The potash resulting was now ready for making soap and glass, as well as for other industrial uses.

Making Pitch andTar

Making Tar from Pine Wood

Discover more from Jacki Kellum

Subscribe to get the latest posts sent to your email.